- #SIEMENS SIMATIC S7 300 REAL TIME MACHINE MONITORING SERIAL#

- #SIEMENS SIMATIC S7 300 REAL TIME MACHINE MONITORING DRIVERS#

- #SIEMENS SIMATIC S7 300 REAL TIME MACHINE MONITORING UPGRADE#

- #SIEMENS SIMATIC S7 300 REAL TIME MACHINE MONITORING SOFTWARE#

A software wizard is also available for configuring the Modbus blocks for Profinet CPUs.įor more information, visit /s7modbus. All Modbus blocks have multi-instance capability.Ĭonfiguration is carried out with Simatic STEP 7. For communication between Simatic stations and other Modbus nodes, native TCP connections that are based on the standard functions of the Simatic S7 library are set up.

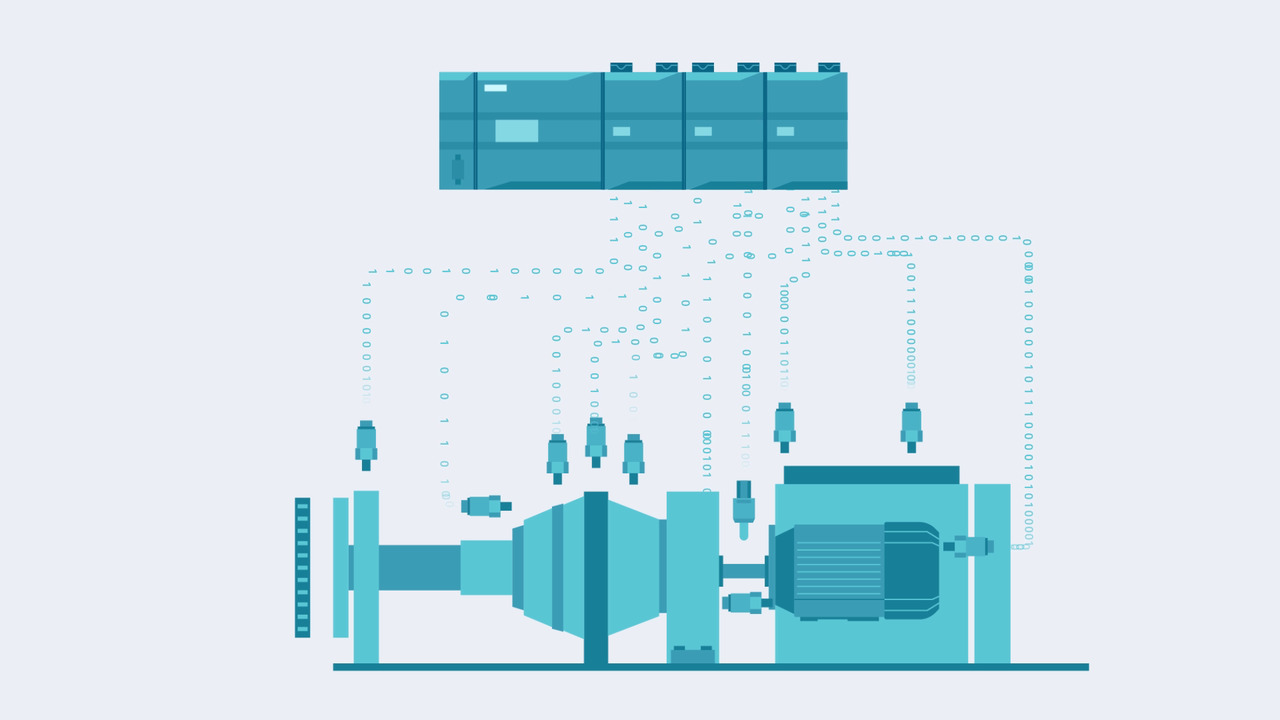

The block with redundancy functionality also makes it possible to establish a communications link that is redundant and therefore fail-safe at the same time. For Simatic S7-400H systems, the Modbus block with redundancy functionality is used and, for communication purposes, a CP443-1 communications processor is needed for each subsystem as well.Īll Modbus variants perform a range of functions supporting server mode, client mode and conformance class 0 with the function codes 3 and 16. For Modbus communication in this case the integrated Profibus interface is used. The Modbus block for central processing units with Profinet capability is used to link up Simatic S7-PN CPUs and ET200S-PN CPUs. For Modbus communication, a CP343-1 or a CP443 1 communications processor is needed as well. There are three Modbus variants available for integrating different Simatic systems: the Modbus block for communications processors is suitable for Simatic S7-300 and S7-400 systems. Simulation tools decrease the time-to-market, diagnostic and energy management functions increase productivity of your plant, and you enjoy greater flexibility and transparency thanks to connect to the management level.Open Modbus/TCP now also supports central processing units with Profinet capability (PN-CPUs), which therefore includes the entire range of Siemens Simatic automation devices. TIA portal provides you with complete access to the entire digitalized automation system, from digital planning to integrated engineering to transparent operation. SIMATIC S7-1200 has dedicated modules which increase the CPU added value offering specific automation tasks: SIMATIC S7-300 the best-selling controller of the Totally Integrated Automation (TIA) product range for factory automation Whether for machine or plant construction the modular SIMATIC® Controllers include a variety of standardized, flexible, and scalable products for sector-independent automation solutions. Connected via Ethernet and scalably to any SIMATIC S7-1200 CPU, the multifunctional platform thus combines the advantages of a cloud with the strengths of a local solution and allows various data collecting and optimization concepts: local, cloud-based and hybrid. Industrial Edge Computing is seamlessly integrated into SIMATIC S7‑1200 by using a technology module as platform for multiple functions: Based on SIMATIC Industrial OS, the SIMATIC S7‑1500 technology module TM MFP is prepared for Siemens Industrial Edge applications on the control level thanks to Edge runtime.

#SIEMENS SIMATIC S7 300 REAL TIME MACHINE MONITORING UPGRADE#

SIMATIC S7-1200 und S7-1500 share the same engineering framework TIA Portal, so in case of reach the maximum possibilities of SIMATIC S7‑1200 it is possible to make a simple controller upgrade to SIMATIC S7‑1500, no migration effort is needed. SIMATIC S7-1200 has technological integrated functions such as HSC, PTO/PWM and Motion Control. It offers support for mixed option using fail-safe and standard I/O assemblies.

Safety Integrated means the easy connection of PROFIsafe devices via PROFIBUS and PROFINET, and data consistency between standard and fail-safe program components. One system for standard and fail-safe applications: One controller, one communication system, and one engineering environment for standard and fail-safe automation. Security Integrated protects your investments, helps prevent the reproduction of machines, and helps to ensure a high level of plant availability.

The security concept of SIMATIC S7-1200 includes communication integrity.

#SIEMENS SIMATIC S7 300 REAL TIME MACHINE MONITORING DRIVERS#

Those attributes are the best foundation for digitalization and are the drivers of new applications and business models such as predictive maintenance or machine learning.

#SIEMENS SIMATIC S7 300 REAL TIME MACHINE MONITORING SERIAL#

They feature a comprehensive range of technological functions and integrated communication as well as especially compact and space-saving design.Ĭommunication modules increase the versatility of SIMATIC S7-1200 offering several open communication protocols as serial communication, PROFIBUS, IO-Link, AS‑Interface, PROFINET, Industrial Ethernet, Telecontrol as well as innovative vertical and horizontal protocols as MQTT and OPC UA providing massive storage and data analisis system possibilities. SIMATIC S7-1200 controllers are the ideal choice when it comes to flexibly and efficiently performing automation tasks in the lower to medium performance range. Be flexible thanks to networking possibilities

0 kommentar(er)

0 kommentar(er)